Above

Notes on Labor - Kumartuli Plastic Ball-Maker

2013

(Enter Full Screen while Viewing)

This artisan is situated in a workshop located few meters away from the printer whom I had begun to follow and collaborate with. In this cramped space he manufactures cheap plastic balls, the type children play with in the side-streets and alleyways within the city. Extremely flimsy, a slight breeze could easily set a ball rolling.

The machine is an old, antiquated, mechanical-electrical piece of equipment. A handfull of colored pellets is fed into a funnel at the top, a sweaty arm swings up and turns a large wheel, a foot pumps what appears to be a bellow placed upon the floor and a set of hands curtly open and close a heavy metal dye. A pearlescent ball emerges, its hemispheres marked by oozing plastic.

The machine is connected to the mains and generates heat that melts the raw plastic.The ball is flipped this way and that a knife deftly slices away the unwanted plastic excess after which the ball is dropped into a bucket of water to cool off.

His movements are economized so as to smoothen the interface between man and machine. The repetitive movements also act as a meter, setting up a schedule that ensures that no motion is missed. And no time wasted. A days work produces about four hundred balls, which are loaded into plastic sacks and then carted away.

Above -

Digital Cut-Outs

Manufactured Balls in a sack

The plastic injection machine in operation

Below -

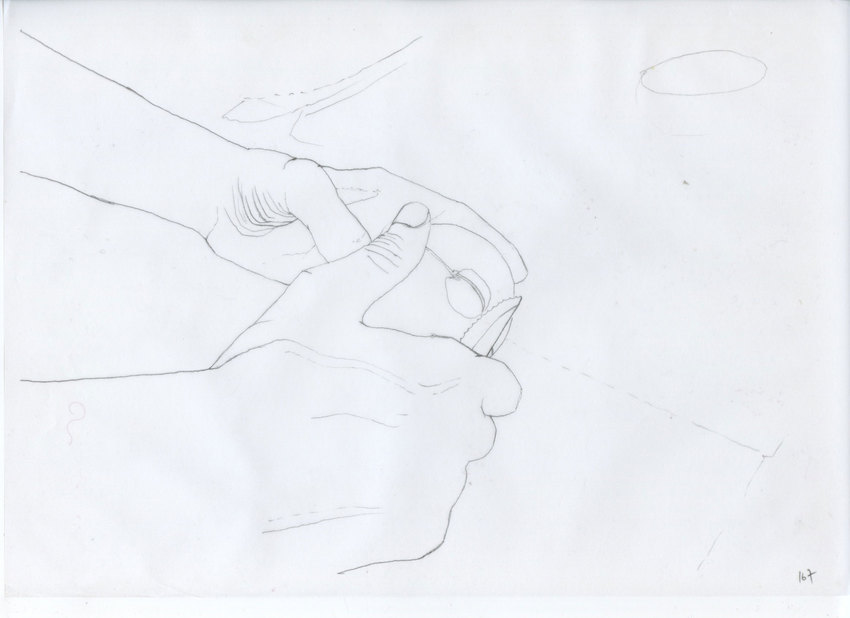

Drawing on A4 paper

Cutting of excess plastic from a newly manufactured plastic ball